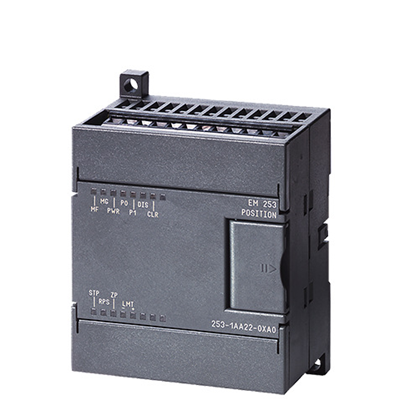

The 6ES7253-1AA22-0XA0 is a positioning module from Siemens’ SIMATIC S7-200 series, specifically the EM 253 model. It is designed to enable precise motion control of stepper motors or servo motors when paired with S7-200 CPUs (e.g., CPU 224, 226), making it suitable for small-scale automation applications requiring accurate positioning, speed control, or synchronized movement.

Key Features & Specifications:

-

Motion Control Capabilities: Supports single-axis positioning with flexible operating modes, including:

- Absolute positioning (target position relative to a fixed reference point).

- Relative positioning (target position relative to the current position).

- Continuous rotation (for speed-controlled operations).

- Jog mode (manual incremental movement for setup or adjustment).

-

Pulse Output: Generates pulse trains to control motor drives, with a maximum pulse frequency of 200 kHz—enabling high-speed, precise movement for applications like small CNC machines, packaging equipment, or material handling systems.

-

Input/Output Signals: Includes dedicated digital inputs and outputs for integration with motor drives and feedback systems:

- Inputs for reference point detection (home position), limit switches (end stops), or external start triggers.

- Outputs to signal drive enable, alarm states, or motion completion, ensuring safe and coordinated operation.

-

Parameterization & Programming: Configured via Siemens’ STEP 7-Micro/WIN software, which provides a user-friendly Positioning Wizard to simplify setup. This wizard guides users through defining motion parameters (speed, acceleration, target positions) without requiring deep motion control expertise.

-

Compatibility: Seamlessly integrates with S7-200 CPUs via the expansion bus, drawing power from the CPU or an external 24 V DC supply. It works with most standard stepper or servo drives that accept pulse/direction or CW/CCW (clockwise/counterclockwise) control signals.

Industrial Integration:

- Mounting: Designed for DIN rail installation, fitting compactly into control cabinets alongside S7-200 CPUs and other expansion modules.

- Reliability: Operates in industrial environments with a temperature range of 0°C to 55°C and complies with EMC (electromagnetic compatibility) standards, ensuring stability in noisy factory settings.

Applications:

Ideal for small-scale motion control scenarios requiring precision, such as:

- Positioning of axes in small CNC routers, 3D printers, or labeling machines.

- Controlling feed mechanisms in packaging or assembly lines.

- Adjusting tool positions in automated inspection systems.

- Synchronizing movements in material handling (e.g., conveyor belt positioning).

The EM 253 module extends the S7-200’s capabilities by adding dedicated positioning functionality, offering a cost-effective solution for applications where accurate motion control is critical but scale is limited.

PLC

PLC

S7-200

S7-200

LED lamps

LED lamps

ABB

ABB

Reviews

Clear filtersThere are no reviews yet.