6AV2124-1MC01-0AX0 is a Siemens SIMATIC HMI KTP1900 Comfort Panel, a high-performance human-machine interface (HMI) designed to support advanced monitoring, control, and visualization in complex industrial automation environments. As part of Siemens’ SIMATIC HMI Comfort Panels series, it builds on basic functionality with enhanced features, making it suitable for medium to large-scale applications requiring sophisticated process interaction and integration. Here’s a detailed overview:

-

Core Purpose: This panel serves as a central operator interface for managing intricate industrial processes, enabling real-time monitoring of multiple parameters, efficient alarm handling, and execution of complex control commands. It is ideal for applications such as multi-line production facilities, advanced machinery, or process plants where detailed data visualization and flexible operator input are critical.

-

Display and User Interaction: It features a 19-inch color touchscreen with a Full HD resolution (1920 x 1080 pixels), delivering sharp, high-contrast visuals for clear presentation of dynamic process data, multi-layered graphics, trend analysis, and custom mimic diagrams. The touchscreen supports multi-touch gestures (e.g., pinch-to-zoom, swipe) for intuitive navigation, even when operators use gloves. Complementing the touch interface is an integrated keypad with programmable function keys, offering a hybrid input method that balances speed, precision, and adaptability to diverse operational needs.

-

Connectivity and Integration: To ensure seamless communication within industrial ecosystems, the panel is equipped with robust interfaces:

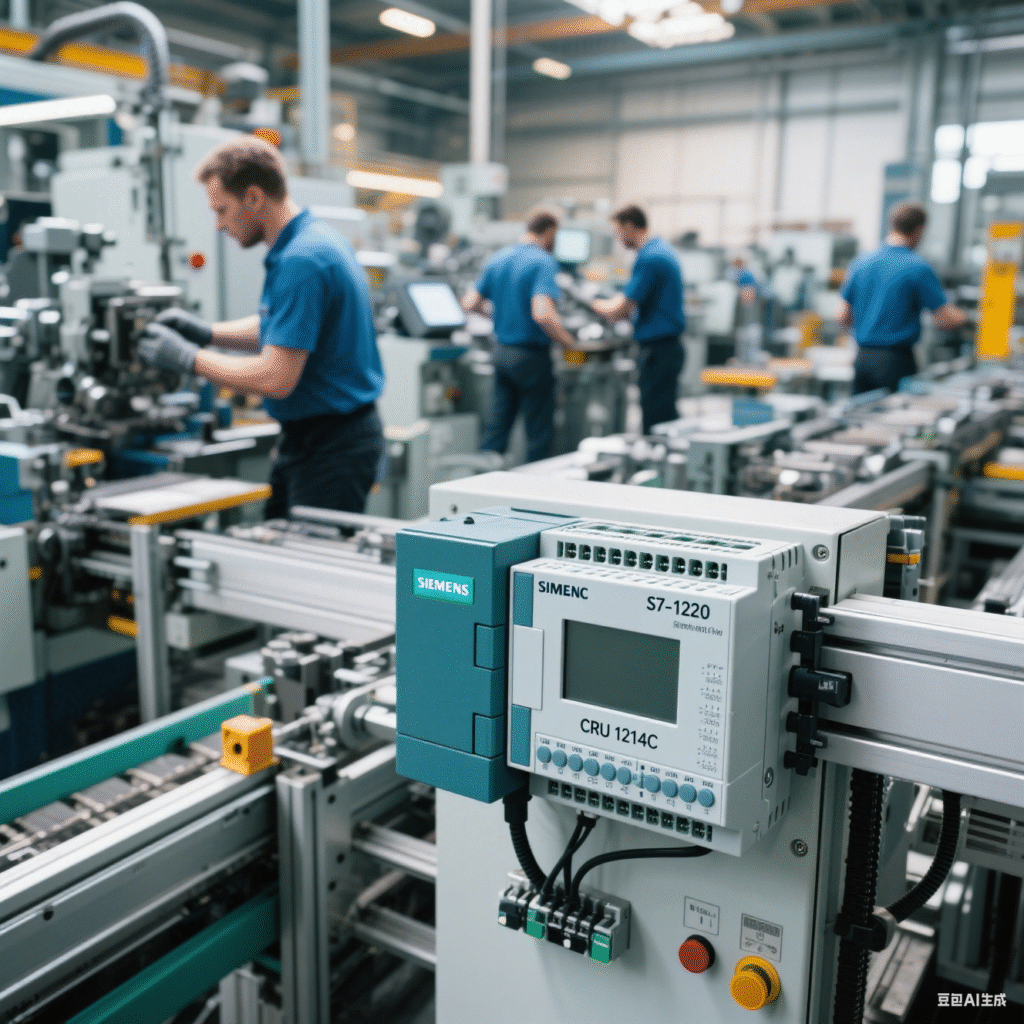

- A PROFINET interface enables high-speed, real-time data exchange with SIMATIC PLCs (e.g., S7-1200, S7-1500), drives, and other PROFINET-compatible devices, supporting efficient networked automation.

- USB ports facilitate configuration, data transfer (e.g., log files, project backups), and connection of peripherals like mice, keyboards, or barcode scanners during setup or maintenance.

- Optional expansion modules may support additional protocols (e.g., Modbus) for integration with third-party devices, enhancing flexibility in mixed-vendor environments.

-

Software and Programming: Configuration is performed using Siemens TIA Portal (Totally Integrated Automation) with WinCC Comfort or WinCC Advanced software, enabling streamlined project development. The TIA Portal integration simplifies synchronization with other SIMATIC components (PLCs, sensors, drives), allowing for a unified automation solution with shared data management and reduced engineering effort. It supports advanced scripting, custom faceplates, and dynamic screen navigation to tailor the interface to specific process requirements.

-

Design and Durability: Built for industrial robustness, the panel features a rugged construction with an IP65 protection rating on the front (resistant to dust and low-pressure water jets) and IP20 at the rear, making it suitable for installation in control cabinets or directly on machinery in harsh environments. It supports flexible mounting options (flush or surface mounting) and has compact dimensions (approximately 482 mm x 313 mm x 55 mm, depending on configuration) to fit efficiently in industrial spaces.

-

Advanced Features: Tailored for complex operations, it offers enhanced capabilities:

- Sophisticated Data Visualization: Supports real-time and historical trend analysis, multi-variable process displays, and interactive graphics for in-depth process monitoring.

- Comprehensive Alarm Management: Advanced alarm handling with prioritization, categorization, timestamping, and logging, including alarm acknowledgment workflows and integration with process data for root-cause analysis.

- Recipe Management: Enables storage, selection, and modification of production recipes, streamlining batch processing and product changeovers.

- User Administration: Supports role-based access control (RBAC) to restrict operations based on user permissions, enhancing security and compliance with operational protocols.

- Diagnostics and Maintenance Tools: Built-in diagnostics for system health monitoring, simplifying troubleshooting and reducing downtime.

-

Environmental and Operational Parameters: It operates in a temperature range of 0°C to 50°C (32°F to 122°F) and can be stored at -20°C to 60°C (-4°F to 140°F). It is designed to withstand industrial vibrations and shocks per relevant standards (e.g., IEC 61131-2), ensuring reliable performance in manufacturing, automotive, food and beverage, or energy sectors.

-

Certifications: Complies with international standards, including CE, UL, and cUL, ensuring adherence to global safety, EMC, and performance regulations for industrial equipment.

With its large high-resolution display, advanced connectivity, and robust feature set, the 6AV2124-1MC01-0AX0 is engineered to meet the demands of complex industrial automation, providing operators with a powerful, intuitive tool to manage and optimize critical processes.

PLC

PLC

S7-200

S7-200

LED lamps

LED lamps

ABB

ABB

Reviews

Clear filtersThere are no reviews yet.