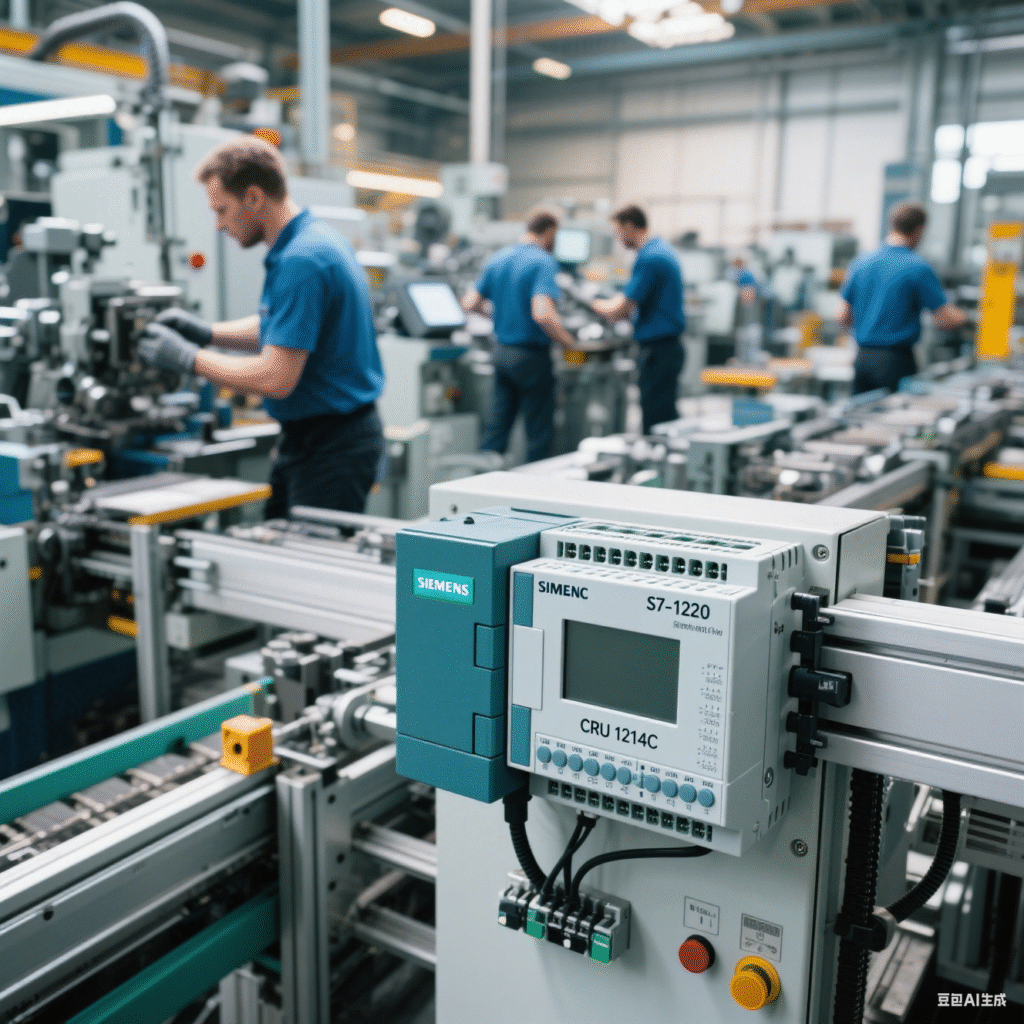

The 6ES7215-1BG40-0XB0 is a high-performance CPU module from Siemens’ SIMATIC S7-200 SMART series, specifically the CPU SR60 model. Designed for medium to large-scale automation applications, it combines robust processing capabilities, expanded digital I/O, and advanced communication features in a compact form factor, making it ideal for controlling complex DC-powered machinery, production lines, or integrated process systems requiring high I/O density and reliability.

Key Features & Specifications:

- Digital I/O Configuration: Equipped with 24 digital inputs and 16 digital outputs (40 total I/O points) to interface with a broad range of industrial sensors and actuators:

- Inputs: 24 V DC (sinking/sourcing) with fast response times, compatible with devices like limit switches, photoelectric sensors, proximity detectors, encoder signals, or safety interlocks.

- Outputs: Transistor-type (24 V DC), optimized for switching DC loads such as solenoids, DC relays, servo drives, variable-speed motors, or precision actuators, ensuring efficient control of low to medium-power DC devices.

- Processing Capability: Features a high-performance microprocessor tailored for complex logic operations, advanced timer/counter functions, arithmetic tasks, and basic motion control. It delivers fast instruction execution (e.g., basic logic in ~0.15 µs), ensuring precise and responsive control in time-critical medium to large-scale processes.

- Memory: Includes 20 KB of program memory (for storing user logic) and 14 KB of data memory (for variables, timers, counters, and data logging), providing ample capacity for large automation tasks with room for program expansion, data storage, and complex sequence management.

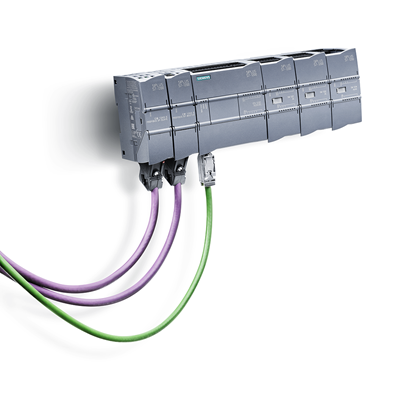

- Communication: Integrates a built-in PROFINET interface (Ethernet port) to support industrial Ethernet communication. This enables seamless connection to HMI panels (e.g., SIMATIC HMI SMART Line or KTP series), programming devices, or other PROFINET-enabled equipment, facilitating network integration, remote monitoring, and real-time data exchange.

- Expandability: Supports up to 8 expansion modules (e.g., additional digital I/O, analog I/O, communication modules, positioning modules, or temperature modules), allowing users to scale I/O capacity or add specialized functions (such as analog control, motion positioning, or temperature monitoring) as application requirements grow.

Integration & Compatibility:

- Power Supply: Operates on DC 24 V, making it suitable for systems with direct current power sources, such as industrial machinery, mobile equipment, or DC-powered production cells.

- Programming: Configured and programmed using Siemens’ TIA Portal software (version V13 and later), which offers an intuitive environment for ladder logic, structured text, or function block diagram programming, simplifying setup, debugging, and maintenance of complex automation logic.

- Mounting: Designed for DIN rail mounting, fitting compactly into control cabinets alongside other industrial components, optimizing space in tight enclosures while ensuring secure installation.

Industrial Durability:

- Withstands harsh industrial conditions, including an operating temperature range of 0°C to 60°C, and compliance with EMC (electromagnetic compatibility) standards. This ensures reliable performance in factory floors, machine enclosures, or environments with electrical noise, vibration, and temperature fluctuations.

Applications:

Ideal for medium to large-scale automation scenarios requiring high I/O density and DC load control, such as:

- Control of complex DC-powered machinery (e.g., automated assembly lines, high-speed packaging systems, or material handling equipment with multiple sensors and actuators).

- Integrated production cells where precise coordination of DC devices (e.g., robotic arms, conveyors, or precision valves) is critical.

- Scalable systems needing extensive I/O or specialized functions, such as retrofitted lines, expanding manufacturing setups, or process control systems with diverse monitoring and actuation needs.

The 6ES7215-1BG40-0XB0 balances processing power, high I/O capacity, and modern connectivity, making it a versatile solution for medium to large-scale automation needs within the SIMATIC S7-200 SMART ecosystem.

PLC

PLC

S7-200

S7-200

LED lamps

LED lamps

Reviews

Clear filtersThere are no reviews yet.